The Art of Creating Cheese

Cheese-making has been a craft passed down through generations. It combines simple ingredients like milk, rennet, and salt to create a wide range of flavors and textures.

The art of crafting cheese lies in the careful control of temperature, timing, and fermentation. While modern technology has influenced the process, traditional methods are still at the heart of creating some of the most beloved cheeses. Here are the steps that cheese makers need to take in order to create these wonderful delicacies.

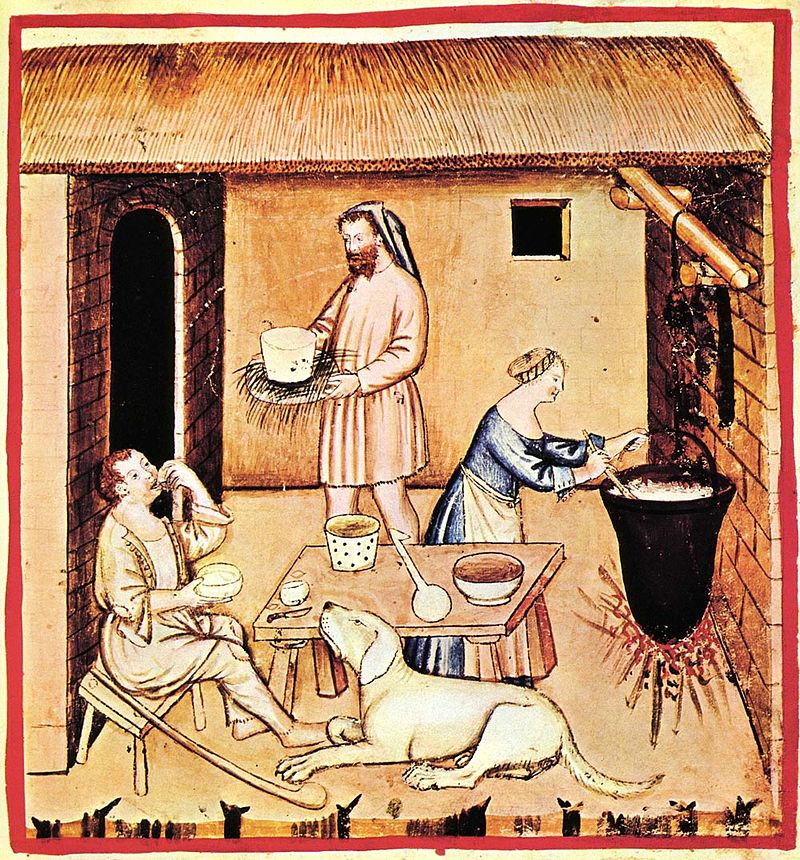

Origins of Cheese-Making

Before we get into the art of creating cheese, we first need to talk about the origins of cheese-making. The beginnings of crafting cheese date back thousands of years. Evidence suggests that cheese was being made in Mesopotamia as early as 6000 BC. The process likely began when people started storing milk in containers made from animal stomachs, which contained natural enzymes that curdled the milk.

By the time of the Roman Empire, cheese-making had spread across Europe, with each region developing its own styles. Pliny the Elder, a Roman scholar, wrote about the wide variety of cheeses available in his time around 77 AD. In the Middle Ages, monasteries in Europe became centers for refining cheese-making techniques, leading to the creation of many varieties that are still enjoyed today.

Basic Ingredients for Cheese-Making

Cheese-making requires only a few basic ingredients, but each plays an important role in creating different types of cheese. These ingredients work together to create the texture and flavor that cheese is known for.

- Milk: The primary ingredient in all cheese-making. It can come from cows, goats, sheep, or other animals. The type of milk affects the flavor and texture of the cheese.

- Starter Cultures: Bacteria that help ferment the milk. They produce lactic acid, which is essential for developing flavor and texture.

- Rennet: An enzyme used to coagulate the milk and form curds. It can be sourced from animals or made from plants and microbes.

- Salt: This is used to enhance flavor and preserve the cheese. It also helps control moisture and the growth of bacteria.

The Cheese-Making Process

Cheese-making follows a series of steps that take simple ingredients and turn them into a variety of cheeses.

Milk Preparation

The process starts with preparing the milk. It is usually pasteurized to kill harmful bacteria, but some traditional cheeses use raw milk. The quality of the milk directly influences the cheese, so it is important that it is fresh and clean.

During this stage, cultures are added to the milk to begin fermentation. These cultures start the process of turning lactose into lactic acid, which helps develop the flavor and texture of the cheese. The milk is then left to ripen for a period of time.

Coagulation

Next, rennet is added to the milk to coagulate it. This enzyme causes the milk to curdle, separating the solid curds from the liquid whey. Depending on the type of cheese being made, the mixture is usually left to rest for 30 minutes to a few hours.

Once the milk has coagulated, it forms a gel-like mass. This is the first step in transforming the milk into a solid. The firmness of the curds can vary depending on the recipe.

Cutting the Curds

The curds are then cut to help release more whey. The size of the cuts affects the moisture content of the cheese, with smaller cuts leading to a drier cheese. Large knives or special tools are used to cut the curds into small pieces.

This step also influences the texture of the final cheese. Soft cheeses like brie require larger curds, while harder cheeses like parmesan need smaller ones. Once cut, the curds are often stirred and heated to help expel more whey.

Draining the Whey

After cutting, the whey is drained from the curds. The curds are often placed into molds or cloth to help remove more moisture. The longer the curds are left to drain, the firmer the cheese becomes.

Draining is critical because it affects the final texture of the cheese. Soft cheeses retain more whey, while firm cheeses lose most of it. Sometimes, the curds are pressed to help squeeze out even more whey.

Aging

The final step for many cheeses is aging. During this time, the cheese is stored in a controlled environment where it can develop its flavor and texture. Temperature and humidity are carefully managed to achieve the desired results.

Cheeses can be aged for weeks, months, or even years. The aging process allows the cheese to develop complex flavors, and the longer it is aged, the sharper or more intense the taste becomes.

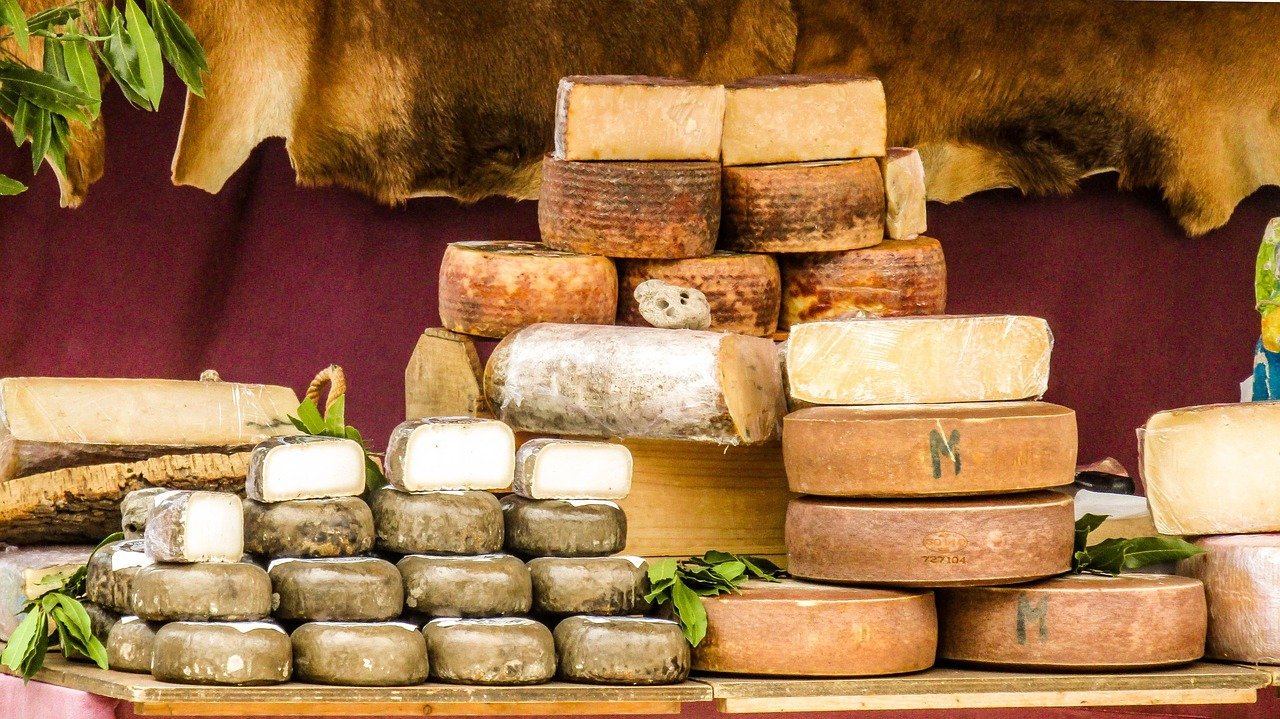

Different Types of Cheese

Cheese comes in many varieties, each with its own texture and flavor. These types of cheese are often classified by how they are made and how long they are aged.

- Fresh Cheese: These cheeses are not aged and have a soft, creamy texture. Examples include ricotta, cream cheese, and cottage cheese. They are usually mild in flavor and have a high moisture content.

- Soft Cheese: Soft cheeses like brie and camembert are ripened from the outside and have a soft, sometimes runny center. They are aged for a shorter period and have a rich, buttery taste.

- Semi-Soft Cheese: Gouda and Havarti are examples of semi-soft cheeses. They have a firmer texture than soft cheeses but are still creamy. These cheeses are often mild to medium in flavor and are aged for a few months.

- Hard Cheese: Hard cheeses like parmesan and cheddar have been aged for longer periods. They are firm in texture, often crumbly, and have a sharper, more intense flavor.

- Blue Cheese: These cheeses are injected with mold to create blue or green veins. Roquefort and Gorgonzola are well-known blue cheeses that have a strong, tangy taste and creamy texture.

Conclusion

The process of making cheese blends tradition and skill. Each step, from choosing the milk to aging the final product, plays a role in shaping the cheese's flavor and texture. While the methods may vary, the craftsmanship remains at the heart of every type of cheese.